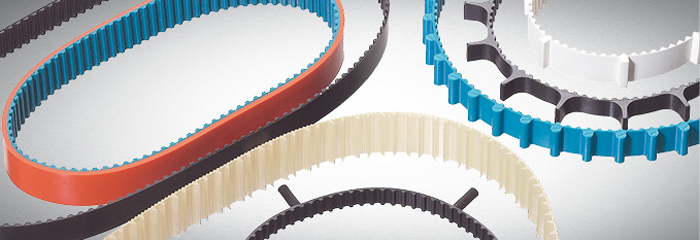

The optibelt DELTA Chain is a new high performance timing belt that sets standards in the market. Up to 100% higher power transmission is possible compared to high performance rubber timing belts.

The overall width of the drive can therefore be considerably reduced. The particular focus is placed here on drives with very high torques. The optibelt DELTA Chain was designed for high torques and delivers high performance even in extreme use and with high loads. With its carbon cord, it is the ideal alternative to drives with roller chains.

The innovative combination of materials with an extremely resistant polyurethane compound, an abrasion-resistant and specially treated polyamide fabric, as well as the carbon fibre cord, make the optibelt DELTA Chain resistant to a wide range of chemicals, oils and fluids.

Sections and lengths |

|

| 8MDC | 640 - 4480 mm |

| 14MDC | 994 - 4410 mm |

| optibelt ZRS DC timing pulleys | and in comparable other brand timing pulleys CTD and PC. |

The powerful optibelt ALPHA POWER timing belts are the result of consistent further development. The extensive experience gained with the ALPHA TORQUE timing belt was brought to bear on this belt generation.

Made with a new, more resistant and more durable polyurethane compound, the performance of this generation is up to 30% higher than that of the previous optibelt ALPHA TORQUE.

By enabling a more compact drive design, the optibelt ALPHA POWER cuts costs, starting with the purchase costs for new belts and pulleys.

The optimised interplay of the polyurethane, with a hardness of 88 Shore A, and the steel cord ensures that the optibelt ALPHA POWER offers an extremely economical solution for a particularly wide range of applications.

Sections and lengths |

|

| T2,5 | 107,50 - 950 mm |

| T5 | 150 - 1440 mm |

| T10 | 260 - 2250 mm |

| AT3 | 150 - 714 mm |

| AT5 | 200 - 1500 mm |

| AT10 | 500 - 1940 mm |

| DT5 | 150 - 1100 mm |

| DT10 | 530 - 1880 mm |

| further dimensions on request | |

Downloads |

|

Product information |

|

Technical manual: Polyurethane timing belt drives |

|

Data Sheets |

|

Technical Data Sheet ALPHA POWER T2,5-ST |

|

Technical Data Sheet ALPHA POWER T5-ST |

|

Technical Data Sheet ALPHA POWER DT5-ST |

|

Technical Data Sheet ALPHA POWER T10-ST |

|

Technical Data Sheet ALPHA POWER DT10-ST |

|

Technical Data Sheet ALPHA POWER AT3-RF |

|

Technical Data Sheet ALPHA POWER AT3-HF |

|

Technical Data Sheet ALPHA POWER AT5-ST |

|

Technical Data Sheet ALPHA POWER AT5-RF |

|

Technical Data Sheet ALPHA POWER AT10-ST |

|

Technical Data Sheet ALPHA POWER AT10-RF |

|

Technical Data Sheet ALPHA POWER T10-RF |

|

Technical Data Sheet ALPHA POWER AT10-HF |

|

Technical Data Sheet ALPHA POWER AT3-AR |

|

The optibelt ALPHA TORQUE is made from abrasion-resistant polyurethane with a hardness of 86 Shore A. Its basic characteristics include unusually good oil resistance for polyurethane, as well as a certain resistance to acids and alkaline solutions.

The optibelt ALPHA TORQUE can be reinforced with tension cords made of steel, highly flexible steel, stainless steel, aramid, polyester or Vectran to suit a wide range of applications.

Sections and lengths |

|

| T2,5 | 107,5 - 950 mm |

| T5 | 150 - 1440 mm |

| T10 | 260 - 2250 mm |

| AT3 | 150 - 714 mm |

| AT5 | 200 - 1500 mm |

| AT10 | 500 - 1940 mm |

| DT5 | 150 - 1100 mm |

| DT10 | 260 - 1880 mm |

| MXL | 60.96 - 812.80 mm |

| XL | 152.40 - 1701.80 mm |

| L | 314.33 - 1524.00 mm |

| further dimensions on request | |

Downloads |

|

Product information |

|

Technical manual: Polyurethane timing belt drives |

|

DATA SHEET |

|

Technical Data Sheet ALPHA TORQUE T2,5-ST |

|

Technical Data Sheet ALPHA TORQUE T2,5-AR |

|

Technical Data Sheet ALPHA TORQUE T5-ST |

|

Technical Data Sheet ALPHA TORQUE T5-AR |

|

Technical Data Sheet ALPHA TORQUE T5-HF |

|

Technical Data Sheet ALPHA TORQUE T5-RF |

|

Technical Data Sheet ALPHA TORQUE T10-ST |

|

Technical Data Sheet ALPHA TORQUE T10-AR |

|

Technical Data Sheet ALPHA TORQUE T10-RF |

|

Technical Data Sheet ALPHA TORQUE DT5-AR |

|

Technical Data Sheet ALPHA TORQUE DT10-ST |

|

Technical Data Sheet ALPHA TORQUE AT5-ST |

|

Technical Data Sheet ALPHA TORQUE AT10-ST |

|

Technical Data Sheet ALPHA TORQUE L-ST |

|

Technical Data Sheet ALPHA TORQUE AT5-RF |

|

Technical Data Sheet ALPHA TORQUE AT3-RF |

|

Technical Data Sheet ALPHA TORQUE AT3-AR |

|

Technical Data Sheet ALPHA TORQUE AT5-AR |

|

Technical Data Sheet ALPHA TORQUE AT10-AR |

|

Technical Data Sheet ALPHA TORQUE DT2,5-ST |

|

Technical Data Sheet ALPHA TORQUE XL-ST |

|

Technical Data Sheet ALPHA TORQUE AT10-RF |

|

Technical Data Sheet ALPHA TORQUE DT5-ST |

|

Technical Data Sheet ALPHA TORQUE T10-AV |

|

Technical Data Sheet ALPHA TORQUE AT5-HF |

|

Technical Data Sheet ALPHA TORQUE AT3-HF |

|

Technical Data Sheet ALPHA TORQUE AT10-HF |

|

The optibelt ALPHA FLEX timing belt is manufactured to the customer’s length specification as an endless belt without any breaks in the tensile reinforcement. This means that two spirally wound tension cords are used.

These

cords can be made of steel, highly flexible steel or stainless steel to suit a wide range of applications.

In the case of belts that are at least 1,500 mm long, the tooth side of the optibelt ALPHA FLEX can be covered with

polyamide fabric (PAZ).

|

Sections and lengths

|

|

| T5 | 1100 - 12000 mm |

| T10 | 1100 - 12000 mm |

| T20 | 1500 - 12000 mm |

| AT5 | 1100 - 12000 mm |

| AT5K6 | 1100 - 12000 mm |

| AT10 | 1100 - 12000 mm |

| AT20 | 1500 - 12000 mm |

| 5M | 1100 - 12000 mm |

| 8M | 1104 - 12000 mm |

| 14M | 1512 - 11998 mm |

| H | 59,5 - 472 in |

| further dimensions on request | |

|

Downloads

|

|

|

Product information |

|

|

Technical manual: Polyurethane timing belt drives |

|

|

Datasheet

|

|

|

Technical Data Sheet ALPHA FLEX T10-HF |

|

|

Technical Data Sheet ALPHA FLEX 14M-ST |

|

|

Technical Data Sheet ALPHA FLEX 5M-ST |

|

|

Technical Data Sheet ALPHA FLEX 8M-ST |

|

|

Technical Data Sheet ALPHA FLEX AT5-ST |

|

|

Technical Data Sheet ALPHA FLEX AT10-HF |

|

|

Technical Data Sheet ALPHA FLEX AT10-ST |

|

|

Technical Data Sheet ALPHA FLEX AT20-ST |

|

|

Technical Data Sheet ALPHA FLEX H-ST |

|

|

Technical Data Sheet ALPHA FLEX T5-ST |

|

|

Technical Data Sheet ALPHA FLEX T10-ST |

|

|

Technical Data Sheet ALPHA FLEX T20-ST |

|

|

Technical Data Sheet ALPHA FLEX AT10-RF |

|

|

Technical Data Sheet ALPHA FLEX AT20-RF |

|

|

Technical Data Sheet ALPHA FLEX T10-RF |

|

|

Technical Data Sheet ALPHA FLEX 8M-RF |

|

|

Technical Data Sheet ALPHA FLEX 8M-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX AT10-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX T10-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX AT20-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX 8M-HF |

|

|

Technical Data Sheet ALPHA FLEX AT5-HF |

|

|

Technical Data Sheet ALPHA FLEX AT5-RF FDA-transparent |

|

|

Technical Data Sheet ALPHA FLEX 5M-RF |

|

|

Technical Data Sheet ALPHA FLEX AT20 HP - ST |

|

|

Technical Data Sheet ALPHA FLEX T20-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX AT5 HP ST |

|

|

Technical Data Sheet ALPHA FLEX AT5 HP HF |

|

|

Technical Data Sheet ALPHA FLEX AT5 HP RF |

|

|

Technical Data Sheet ALPHA FLEX 5M-RF FDA-transparent |

|

|

Technical Data Sheet ALPHA FLEX T20-RF |

|

|

Technical Data Sheet ALPHA FLEX H-HF |

|

|

Technical Data Sheet ALPHA FLEX 5M-HF |

|

|

Technical Data Sheet ALPHA FLEX AT20 HP - RF |

|

|

Technical Data Sheet ALPHA FLEX T20-HF |

|

|

Technical Data Sheet ALPHA FLEX H-RF |

|

|

Technical Data Sheet ALPHA FLEX H-RF-PU85 |

|

|

Technical Data Sheet ALPHA FLEX 14M-RF |

|

|

Technical Data Sheet ALPHA FLEX AT5K6-ST |

|

|

Technical Data Sheet ALPHA FLEX AT5K6-ST |

|

|

Technical Data Sheet ALPHA FLEX 14M-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX H-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX AT10K13-ST |

|

|

Technical Data Sheet ALPHA FLEX AT5K6-RF |

|

|

Technical Data Sheet ALPHA FLEX AT5 HP RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX AT5-RF |

|

|

Technical Data Sheet ALPHA FLEX AT5K6-RF FDA transparent |

|

|

Technical Data Sheet ALPHA FLEX T5-HF |

|

|

Technical Data Sheet ALPHA FLEX T5-HF PU-85 Shore A |

|

|

Technical Data Sheet ALPHA FLEX T5K6-ST |

|

|

Technical Data Sheet ALPHA FLEX T5K6-HF |

|

|

Technical Data Sheet ALPHA FLEX T5K6-HF |

|

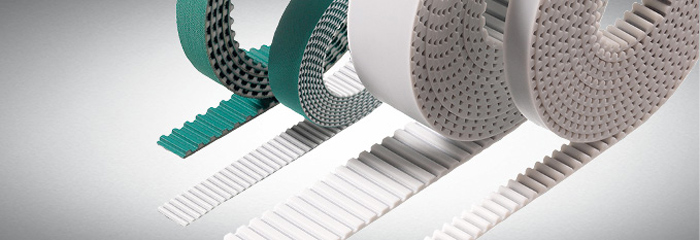

Open-ended optibelt ALPHA LINEAR timing belts are made of extruded, thermoplastic polyurethane with tension cords parallel to the edges. The belts are dimensionally stable and their precise positioning makes them ideal for use in linear drive systems.

Alternatively to the “reinforced top surface” version, it is also possible to apply transparent polyurethane (with a hardness of 85 Shore A) with the designation T2, or yellow PU foam or other materials and versions directly to the belt in an additional downstream extrusion process.

The optibelt ALPHA LINEAR timing belt can also be given a thin fabric covering on the tooth side in order to reduce friction and noise. Fabric can also be applied to the belt back.

Sections and lengths |

|

| XL; L; H; XH | Roll length 50 m or 100 m |

| 5M; 8M; 8ML; 14M; 14ML; 14MLP | Roll length 50 m or 100 m |

| T5; T10; T20 | Roll length 50 m or 100 m |

| AT5; AT10; AT20 | Roll length 50 m or 100 m |

| ATL5; ATL10; ATL20 | Roll length 50 m or 100 m |

| F2; F2,5; F3; F4,5; FL3 | Roll length 50 m or 100 m |

| > 100 m available on request | |

| further dimensions on request | |

Downloads |

|

Product information - Timing belts |

|

Technical manual: Polyurethane timing belt drives |

|

Product information - Track timing belts |

|

Data Sheets |

|

Technical Data Sheet ALPHA LINEAR T10-ST |

|

Technical Data Sheet ALPHA LINEAR T10-AR |

|

Technical Data Sheet ALPHA LINEAR AT5-ST |

|

Technical Data Sheet ALPHA LINEAR AT10-ST |

|

Technical Data Sheet ALPHA LINEAR H-ST |

|

Technical Data Sheet ALPHA LINEAR 8M-ST |

|

Technical Data Sheet ALPHA LINEAR AT10K6-RF blue |

|

Technical Data Sheet ALPHA LINEAR AT10K6-RF transp. |

|

Technical Data Sheet ALPHA LINEAR AT10K13-RF blue |

|

Technical Data Sheet ALPHA LINEAR AT10K13-RF transp. |

|

Technical Data Sheet ALPHA LINEAR ATL5-ST |

|

Technical Data Sheet ALPHA LINEAR ATL5-HF |

|

Technical Data Sheet ALPHA LINEAR ATL10-ST |

|

Technical Data Sheet ALPHA LINEAR L-HF |

|

Technical Data Sheet ALPHA LINEAR XL-ST |

|

Technical Data Sheet ALPHA LINEAR H-AR |

|

Technical Data Sheet ALPHA LINEAR L-ST |

|

Technical Data Sheet ALPHA LINEAR XH-ST |

|

Technical Data Sheet ALPHA LINEAR 14ML-ST |

|

Technical Data Sheet ALPHA LINEAR 8M-AR |

|

Technical Data Sheet ALPHA LINEAR 5M-ST |

|

Technical Data Sheet ALPHA LINEAR AT5-HF |

|

Technical Data Sheet ALPHA LINEAR AT5K6-ST |

|

Technical Data Sheet ALPHA LINEAR AT10K6-ST |

|

Technical Data Sheet ALPHA LINEAR AT10K13-ST |

|

Technical Data Sheet ALPHA LINEAR AT10-RF |

|

Technical Data Sheet ALPHA LINEAR AT10-AR |

|

Technical Data Sheet ALPHA LINEAR AT20-ST |

|

echnical Data Sheet ALPHA LINEAR ATL20-ST |

|

Technical Data Sheet ALPHA LINEAR T5K6-ST |

|

Technical Data Sheet ALPHA LINEAR T5-ST PAZ/PAR antistatic |

|

|

echnical Data Sheet ALPHA LINEAR T10K6-ST |

|

|

Technical Data Sheet ALPHA LINEAR T10K13-ST |

|

|

Technical Data Sheet ALPHA LINEAR T20-ST |

|

|

Technical Data Sheet ALPHA LINEAR T5-ST |

|

|

Technical Data Sheet ALPHA LINEAR F2,5-ST |

|

|

Technical Data Sheet ALPHA LINEAR FL3-ST |

|

|

Technical Data Sheet ALPHA LINEAR F2-ST |

|

|

Technical Data Sheet ALPHA LINEAR F3-ST |

|

|

Technical Data Sheet ALPHA LINEAR F2-AR |

|

|

Technical Data Sheet ALPHA LINEAR 8M-HF |

|

|

Technical Data Sheet ALPHA LINEAR T5-AR |

|

|

Technical Data Sheet ALPHA LINEAR 14M-ST |

|

|

Technical Data Sheet ALPHA LINEAR 8M-RF |

|

|

Technical Data Sheet ALPHA LINEAR T10-HF |

|

|

Technical Data Sheet ALPHA LINEAR T20-HF |

|

|

Technical Data Sheet ALPHA LINEAR T10K13-AR |

|

|

Technical Data Sheet ALPHA LINEAR AT10-HF |

|

|

Technical Data Sheet ALPHA LINEAR T10 groove free - ST |

|

|

Technical Data Sheet ALPHA LINEAR T5-AR FDA blue |

|

|

Technical Data Sheet ALPHA LINEAR S8M-ST |

|

|

Technical Data Sheet ALPHA LINEAR T10-AR HP |

|

|

Technical Data Sheet ALPHA LINEAR 14MLP-ST-PAZ PU PAZ black |

|

|

Technical Data Sheet ALPHA LINEAR T10-RF |

|

|

Technical Data Sheet ALPHA LINEAR H-AR PU FDA transparent |

|

|

Technical Data Sheet ALPHA LINEAR AT10K13-HF |

|

|

Technical Data Sheet ALPHA LINEAR T10-RF FDA transparent |

|

|

Technical Data Sheet ALPHA LINEAR T10-RF FDA blue |

|

|

Technical Data Sheet ALPHA LINEAR AT10-RF PU FDA transparent |

|

|

Technical Data Sheet ALPHA LINEAR 14MLP-ST-PAZ PU white PAZ green |

|

|

Technical Data Sheet ALPHA LINEAR F4,5-ST PU white |

|

|

Technical Data Sheet ALPHA LINEAR F4,5-ST PU black |

|

|

Technical Data Sheet ALPHA LINEAR 8ML-ST PU black |

|

|

Technical Data Sheet ALPHA LINEAR 8ML-ST PU white |

|

|

Technical Data Sheet ALPHA LINEAR AT10-AR PU FDA transparent |

|

|

Technical Data Sheet ALPHA LINEAR F3 groove free - ST PU PAR black |

|

|

Technical Data Sheet ALPHA LINEAR F3 groove free - ST |

|

|

Technical Data Sheet ALPHA LINEAR F2,5 groove free - ST PU PAR black |

|

|

Technical Data Sheet ALPHA LINEAR F2,5 groove free - ST |

|

|

Technical Data Sheet ALPHA LINEAR F2 groove free - ST |

|

|

Technical Data Sheet ALPHA LINEAR F2 groove free - ST PU PAR black |

|

|

Technical Data Sheet ALPHA LINEAR F2-ST PU PAZ black |

|

|

Technical Data Sheet ALPHA LINEAR AT10 HP - ST |

|

|

Technical Data Sheet ALPHA LINEAR DT10-ST |

|

Technical Data Sheet ALPHA LINEAR DAT10-ST |

|

Technical Data Sheet ALPHA LINEAR DAT5-ST |

|

Technical Data Sheet ALPHA LINEAR DT5-ST |

|

Technical Data Sheet ALPHA LINEAR AT10K6-HF |

|

Technical Data Sheet ALPHA LINEAR F2-HF |

|

Technical Data Sheet ALPHA LINEAR AT5-AR |

|

Technical Data Sheet ALPHA LINEAR 5M-AR |

|

Technical Data Sheet ALPHA LINEAR 25-32-75 ATC10-ST |

|

Technical Data Sheet ALPHA LINEAR 50-100-150 ATC10-ST |

|

Technical Data Sheet ALPHA LINEAR 50-100-150 ATC20-ST |

|

Technical Data Sheet ALPHA LINEAR 50-100 ATC10K6-ST |

|

Optibelt ALPHA V timing belts are made from open-ended, extruded optibelt ALPHA LINEAR timing belts that are welded together to achieve the specified length. These are ideal for conveying technology.

Despite the break in the tension cords at the finger spliced joint, the welded timing belts still achieve at least 50% of the permissible tractive force achieved by belts with continuous cords. This is due to the high strength of the thermoplastic polyurethane.

When polyamide fabric is welded to the polyurethane belts, the fabric is simply butt jointed and not bonded together at its ends. In contrast, the coatings of reinforced top surfaces, T2, yellow PU foam and APL plus coatings as well as the tooth side of the belt can be welded without a joint as a composite.

Sections and lengths |

|

| XL; L; H; XH | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| 5M; 8M; 14M | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| T5; T10; T20 | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| AT5; AT10; AT20 | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| T5K6; T10K6; T10K13; | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| AT5K6; AT10K6; AT10K13 | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

| F2; F2,5; F3; FL3 | Minimum welding lengths 400 to 1200 mm, depending on width and pitch |

Downloads |

|

Product information - optibelt ALPHA V |

|

Technical manual: Polyurethane timing belt drives |

|

DATA SHEETS |

|

Technical Data Sheet ALPHA V T10-ST |

|

Technical Data Sheet ALPHA V T10-AR |

|

Technical Data Sheet ALPHA V AT5-ST |

|

Technical Data Sheet ALPHA V AT10-ST |

|

Technical Data Sheet ALPHA V H-ST |

|

Technical Data Sheet ALPHA V 8M-ST |

|

Technical Data Sheet ALPHA V AT10K6-RF blue |

|

Technical Data Sheet ALPHA V AT10K6-RF transp. |

|

Technical Data Sheet ALPHA V AT10K13-RF blue |

|

Technical Data Sheet ALPHA V AT10K13-RF transp. |

|

Technical Data Sheet ALPHA V AT5-HF |

|

Technical Data Sheet ALPHA V AT5K6-ST |

|

Technical Data Sheet ALPHA V AT10K6-ST |

|

Technical Data Sheet ALPHA V AT10K13-ST |

|

Technical Data Sheet ALPHA V AT10-RF |

|

Technical Data Sheet ALPHA V L-HF |

|

Technical Data Sheet ALPHA V XL-ST |

|

Technical Data Sheet ALPHA V XH-ST |

|

Technical Data Sheet ALPHA V T5K6-ST |

|

Technical Data Sheet ALPHA V T5-ST PAZ/PAR antistatic |

|

Technical Data Sheet ALPHA V T10K6-ST |

|

Technical Data Sheet ALPHA V T10K13-ST |

|

Technical Data Sheet ALPHA V T5-ST |

|

Technical Data Sheet ALPHA V L-ST |

|

Technical Data Sheet ALPHA V T5-AR |

|

Technical Data Sheet ALPHA V 8M-HF |

|

Technical Data Sheet ALPHA V T10K13-AR |

|

Technical Data Sheet ALPHA V T5-AR FDA blue |

|

Technical Data Sheet ALPHA V 5M-ST |

|

Technical Data Sheet ALPHA V T10-AR HP |

|

Technical Data Sheet ALPHA V 14M-ST |

|

Technical Data Sheet ALPHA V T10-RF |

|

Technical Data Sheet ALPHA V H-AR PU FDA transparent |

|

Technical Data Sheet ALPHA V AT10K13-HF |

|

Technical Data Sheet ALPHA V AT20-ST |

|

Technical Data Sheet ALPHA V T20-ST |

|

Technical Data Sheet ALPHA V T10-RF FDA transparent |

|

Technical Data Sheet ALPHA V T10-RF FDA blue |

|

Technical Data Sheet ALPHA V AT10-HF |

|

Technical Data Sheet ALPHA V AT10-RF PU FDA transparent |

|

Technical Data Sheet ALPHA V T10-HF |

|

Technical Data Sheet ALPHA V AT10-AR |

|

Technical Data Sheet ALPHA V AT10-AR PU FDA transparent |

|

Technical Data Sheet ALPHA V F2-ST |

|

Technical Data Sheet ALPHA V F2 groove free - ST - PU/PAR black |

|

Technical Data Sheet ALPHA V F2 groove free - ST |

|

Technical Data Sheet ALPHA V F2-AR |

|

Technical Data Sheet ALPHA V F2,5-ST |

|

Technical Data Sheet ALPHA V F2,5 groove free - ST |

|

Technical Data Sheet ALPHA V F2,5 groove free - ST |

|

Technical Data Sheet ALPHA V F2,5 groove free - ST - PU/PAR black |

|

Technical Data Sheet ALPHA V F3-ST |

|

Technical Data Sheet ALPHA V F3 groove free - ST |

|

Technical Data Sheet ALPHA V F3 groove free - ST - PU/PAR black |

|

Technical Data Sheet ALPHA V TEXTILE POWER TT5-AR |

|

Technical Data Sheet ALPHA V F2-ST PU PAZ black |

|

Technical Data Sheet ALPHA V AT10 HP - ST |

|

Technical Data Sheet ALPHA V DT10-ST |

|

Technical Data Sheet ALPHA V DAT10-ST |

|

Technical Data Sheet ALPHA V DAT5-ST |

|

Technical Data Sheet ALPHA V DT5-ST |

|

Technical Data Sheet ALPHA V AT10K6-HF |

|

Technical Data Sheet ALPHA V T20-HF |

|

Technical Data Sheet ALPHA V F2--HF |

|

Technical Data Sheet ALPHA V AT5-AR |

|

Technical Data Sheet ALPHA V 5M-AR |

|

Technical Data Sheet ALPHA V 25-32-75 ATC10-ST |

|

Technical Data Sheet ALPHA V 50-100-150 ATC20-ST |

|

Technical Data Sheet ALPHA V 50-100-150 ATC10-ST |

|

Technical Data Sheet ALPHA V 8M-RF |

|

Technical Data Sheet ALPHA V 50-100 ATC10K6-ST |

|

The ZS / ZSi timing belt lock

is designed to allow repeated detaching and joining of timing belts in the system itself. Versions are available for AT10, T10 and H profiles.

Both versions are offered in

stainless steel as standard for the AT10 and H profiles. For the T10 profile, the tooth-side inserts are made of brass.

PINJOIN timing belt lock

The PINJOIN timing belt lock is designed for permanently joining belts, once only, in the system. Version available for profile AT10.

The connection is made with stainless steel

threaded pins that fit into laterally drilled holes running longitudinally through the tooth.

|

Sections and lengths

|

|

| T10 / AT10 | width 25, 32 and 50 mm |

| H | width 25,4 38,1 and 50,8 mm |

| Further profiles - intermediate widths and widths | exceeding 50 mm are available on request |

|

Downloads

|

|

|

Technical manual: Polyurethane timing belt drives |

|

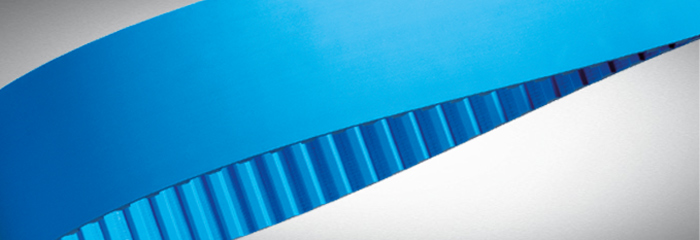

Optibelt ALPHA linear and ALPHA V timing belts in the FDA blue version are produced from a PU base material with FDA approval for the direct transport of foodstuffs, and thus expand the wide range of Optibelt polyurethane timing belts.

The blue timing belt has a hardness of 85 Shore A and is optionally equipped with an aramid or stainless steel tension cord. Profiles T5 and T10 with aramid cord are available from stock. The other profiles listed on the left are

manufactured on request.

The thermoplastic polyurethane is eminently suitable for welding on the cleats made of FDA-approved base material. Base material, with a hardness and colours options to match those of the base belt.

In addition, the optibelt ALPHA V timing belt can be provided with top surface coatings, which are also made of FDA-approved base material.

|

Sections and lengths

|

|

| T5 - aramid tension cord | Joined endless from 1000 mm, shorter lengths on request |

| T10 - aramid tension cord | Joined endless from 1000 mm, shorter lengths on request |

| T10 - stainless steel tension cord | Joined endless from 1000 mm, shorter lengths on request |

| T20 - stainless steel tension cord | Joined endless from 1000 mm, shorter lengths on request |

| AT10 - stainless steel tension cord | roll length 50 m or 100 m |

| H - stainless steel tension cord | Joined endless from 1000 mm, shorter lengths on request |

| 8M - stainless steel tension cord | roll length 50 m or 100 m |

| further profiles on request | |

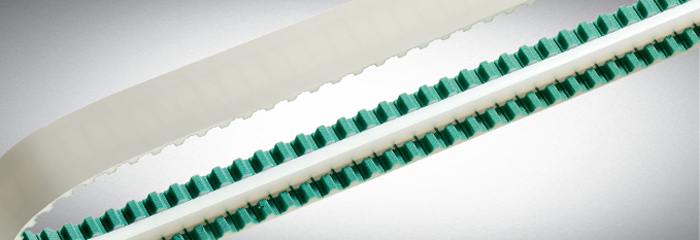

Optibelt ALPHA LINEAR track timing belts are a composite construction of timing belt and V-profile guide, manufactured in one process and thus forming a homogeneous unit.

ALPHA track timing belts are welded open-ended

and can be produced as endlessly welded ALPHA track timing belts.

ALPHA LINEAR track timing belts are mainly used when large lateral forces are a factor and for running on timing belt pulleys when flanged pulleys are not

desirable. The composite timing belt and V-guide construction that is manufactured in one process step results in timing belts that run with precise directional stability.

These belts are commonly used in conveying and

material handling applications.

|

Sections and lengths

|

|

| T5 | Joined endless from 600 mm roll length 50 m |

| T10 | Joined endless from 600 mm roll length 50 m |

| AT5 | Joined endless from 600 mm roll length 50 m |

| AT10 | Joined endless from 600 mm roll length 50 m |

|

Downloads

|

|

|

Technical manual: Polyurethane timing belt drives |

|

The optibelt SRP timing belt with cast cleats and coatings is manufactured in a single production step and used in conveying systems.

The polyurethane is cast between the core mould and the special outer mould with correspondingly

increased internal diameter or special outer moulds with the desired contour for the cleats.

By rotating the inner and outer moulds around the central axis, a Shore hardness that differs from that of the teeth can be cast

using a centrifugal casting process.

|

Sections and lengths

|

|

| The ALPHA SRP moulds are based on those of the ALPHA TORQUE and ALPHA POWER timing belts. | Displacement casting: 120 to 2,250 mm |

| Centrifugal casting: up to 900 mm | |

|

Downloads

|

|

|

Technical manual: Polyurethane timing belt drives |

|

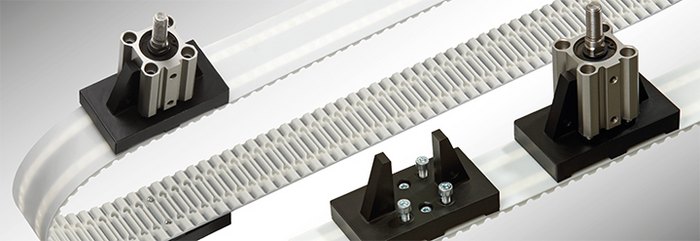

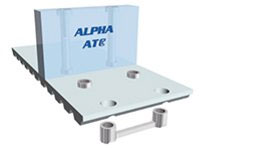

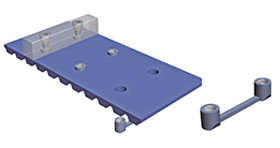

The optibelt ATC-SYSTEM is a patented system solution and comprises an extruded polyurethane timing belt. With its impressed ATC recesses, it offers a cost-effective solution in flexible systems.

The user of the ATC-SYSTEM can fasten screw-on cleats quickly and easily to a freely selectable tooth, on the spot. The connection can be fastened and detached directly by the user. As a result,varying forms of transported goods can be conveyed on the same

drive and base belt using different screw-on cleats. With detachable cleat fastenings, the costs for stock-keeping of wear and spare parts can be reduced.

ATC inserts also make it possible to screw parts on directly, such as highly precise metal workpiece carriers, without using welded-on, specially manufactured cleats with inserts. Furthermore, screw-on cleats can transmit

higher forces in comparison to permanently connected cleats. In addition, a smaller minimum pulley diameter can be chosen for the same fastening strength. Screw-on cleats for the ATC-SYSTEM are available on request.

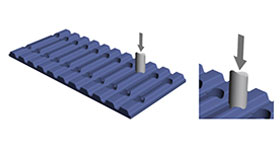

With the ATC-System, an ATC-IN insert for screwing on the cleat is laid into the prepared recess in the tooth. In the optibelt ALPHA V timing belt, these recesses are consistently available in all teeth

in profiles ATC10 and ATC20.

ATC-IN inserts are available in the material qualities stainless steel and zinc (ATC20 only stainless steel) in packaging units á 10, 25 or 100 pieces (ATC20 not in 100).

The assignment to belt profiles and

properties can be found in the optibelt ATC-SYSTEM brochure.

|

Profile and Width mm

|

|

| ATC10 | 25, 32, 50, 75, 100, 150 |

| ATC10K6 | 50, 100 |

| ATC20 | 50, 100, 150 |

|

Minimum length as welded ALPHA V

|

|

| ATC10 | 850mm to 1150mm (width dependent) |

| ATC20 | 1060mm to 1160mm (width dependent) |

|

Roll length

|

|

| optibelt ALPHA LINEAR | 50m or 100m |

|

ATC-IN | Suitable for

|

|

| M4-14RF, M4-14ZN | ATC10 b= 25, 32, 75 |

| M4-25RF, M4-25ZN | ATC10 / ATC10K6 b=50, 100, 150 |

| M5-25RF | ATC20 b=50, 100, 150 |

|

Individual components of the ATC SYSTEM

|

ATC profile with recesses for ATC-IN inserts in each tooth

Punching of a through-hole with ATC-PT punching tool

ATC profile with punched holes for ATC-IN inserts and installation of a screw-on cleat

Office # 7H, Laxmi Industrial Estate,

New Link Road, Andheri (West),

Mumbai - 400053. (India)

All Rights Reserved by Power Belt India Designed by Mirackle Solutions, India